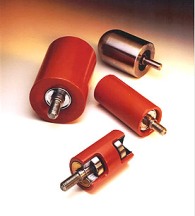

Steel Rollers – EUROTIM Rollers

REPAIR TIRES & TUBES BALKAN d.o.o. is the official distributor of famous high quality EUROTIM d.o.o. rollers

Web-Link EUROTIM Rollers Portfolio:

Basic rollerBasic roller is a steel tube that is used as a bearing or rebound roller on conveyors. It is the most commonly used on standard rollers in quarries, separations, cement and lime factories, transportation ports, silos, sugar refineries, mines, thermal power plants, etc. Due to a sealing system and high quality bearings, the main specificity of our basic rollers is that they are characterized by a typical high resistance to dust, mud, water, and the large difference in temperature between day and night. Operating temperature of the basic roller is between -20°C and +100°C. This hermetically sealing system that protects the bearings and extends maximum lifetime of the roller, as well as quality system ISO 9001:2008, which controls all production inputs, are the best guarantee of the roller durability and customer satisfaction. Standard dimensions of the roller are Ø63, Ø89, Ø108, Ø133 and Ø159 with spindle Ø20 e14mm or Ø25 e18, and all other dimensions are produced on customer request. |

|

|||||||||||||||

Impact rollerImpact rollers are used under the belt on pouring place to protect the belt with its rubber rings from material damage during the incursions. Therefore, they take over the load created by the material incursion and load of material weight on the belt. Base of bearing rollers and dimensions are the same as in the basic roller, the difference is only in the rubber rings which may be in following dimensions : Dimensions of rubber rings on the impact roller:

|

|

|||||||||||||||

Rubber rebound rollerRebound rollers with rubber rings are used to prevent the accumulation of material on the metal roller mantle. Accumulation of material can lead to belt damage or it can move belt from the ideal trajectory. Therefore, besides the role of cleaning and noise reduction, rebound rollers with rubber rings allow better belt centering. Rubber rings can be pointed in order to give the belt a better direction, they can be straight in order to be more burden bearing or they can often be both in combination. Usually one roller is used on stack but they can be used as a pair. The base of rubber rebound rollers and dimensions are the same as in the basic roller, the difference is only in the rubber rings which may be in following dimensions: Dimensions of rubber rings on the rubber rebound roller:

|

|

|||||||||||||||

Side rollerSide rollers or leading rollers are the most effective solution for the self-centering of rubber belts. Their use does not damage the belt even if the belt runs over them. Usually, the dimensions of side rollers are: |

|

|

Plastic Rollers - REMA TIP TOP /LSCE The TQ roller is a completely new and patented transport roller that is manufactured from high quality synthetic material. The innovative features of the TQ rollers are the tube and the bearing cases made entirely from HDPE. This leads to noise-reduced operation, reduces wear and makes the roller 55% lighter than traditional steel rollers. The TQ roller is the solution at locations where noise suppression is a problem. Acoustic measurements have shown that the reduction of ambient noise by 10 dB can be achieved, in comparison to traditional steel rollers. REMA TIP TOP has tested the roller extensively in various sectors: Bulk materials handling, sand and gravel industry, compost and recycling, cement and concrete, glass, compost, fertilising factories and so on.

|

|

|

Technical Data |

|

Industrial Solutions :

|

|

|

|

|

|

|

|

|

|

|

|

Tru Trac Belt Tracking System

|

Tru-Trac Flat Return Tracker The Tru-Trac employs a unique and highly effective tracking action, which is non-damaging to the belt and kicks-in immediately if the belt begins to drift off centre. Because it does not rely on contact with the belt edge in order to guide the belt, belt edge damage, which occurs frequently with other tracking systems, is avoided. Features and Benefits

Non standard trackers can be made to customer specifications |

|

|

Tru-Trac Return Tracker For the alignment of the return side of the conveyor belt. The Dual Return Tracker was developed to accommodate the excessive force encountered with wide belts and heavy loads. An external central pivot mechanism was designed, obviating the need for a single, large drum, and enabling a concentric and balanced rotation to be achieved. Obviously, this results in extended bearing life and a very fast and effective tracking system. Two separate tapered rolls are mounted onto the pivot mechanism, which can be individually replaced as wear occurs. The same award winning features that go into the Flat Return Tracker have been incorporated in the Dual Return Tracker. Features and Benefits

Non standard trackers can be made to customer specifications. |

|

| |

|

|

Heavy Duty Dual Return Tracker

This tracker is designed to operate and last in severe conditions,for high speed belts 5m/s and upwards, heavy duty steel cord conveyor belts 20mm or thicker, high tension belts and aggressive materials like iron ore and coal ash. The Polyurethane lagging has proven to give exceptionally good life in hard wearing applications. Thrust & Roller bearings do an excellent job of handling the excessive side forces. Also available with Greasable bearings, for really extreme conditions. |

|

|

Tru-Trac Trough Tracker - conveyor belt tracking system, troughing idler

For the alignment of the load carrying side of the conveyor belt. The Trough Tracker roller was specifically developed to accommodate the load-carrying side of the conveyor belt. Obviously, due to the throughed nature of this side of the conveyor belt, a different tracking configuration was required. Wing rollers were incorporated into the design to activate our standard central pivot system. The activating wing rolls are set to have a maximum effective contact between the belt edge and the wing roller of 25°-55° (instead of the usual 90°), and are compatible with all throughed belts from 15°-45°. These wing rolls are set to miss the edge of the existing throughed conveyor by between 5mm-10mm on either side. As the conveyor belt moves off-centre the conveyor belt slides up the wing roll and thus causes the Tru-Trac to pivot on its internal pivot and steer the conveyor belt back to centre with minimum force. The unique aspect of the Tru-Trac Trough Tracker roller is that the centre roll does all the steering and not the wing rolls, as this is where the most effective steering forces are exerted. The Tru-Trac series of conveyor belt tracking idlers are a patented design that offers the most reliable and re-active tracking idlers available today. Its stainless steel internal pivot that is perpendicular to the plane of the belt and its rubber covered shell and tapered ends helps actuate the trainer immediately as the conveyor belt moves off center. It is always reacting to keep the conveyor belt centered. It does not wait, like conventional trainers, for the conveyor belt to walk over to 90-degree sensor rollers and then have the belt react. The Tru-Trainer reacts as the belt tracker moves off center it will contact the tapered section of the roller on that side of the conveyor belt. The effect of this will be to force the roller to rotate on its central pivot causing the belt to come back to its original position (centered).

Features and Benefits of the Trough Tracker roller

Non standard trackers can be made to customer specifications |

|

Portfolio Conveyor Belts Overview:

- EP standard belts EP 400/3 – EP 630/4 (supplied through RTT owned Logistiv Service Center Europe-LSCE)

- EP belts with higher tensile strength EP 800/4 – 2.000/5 (width max. 2.400 mm)

- Steelcord belts in the rubber qualities X, Y, W, K, D ST 1.000 –ST 6.300 (width max. 2.400 mm)

- Textile Reinforced PVC Conveyor Belting

Product Range detailed: |

|

| Textile Reinforced Rubber Conveyor Belting SANS 1137 , SANS 971 |

|

|

Full range of rubber cover Qualities Grade N Grade M Grade C DIN X DIN W FR Fire Resistant OR Oil Resistant BVO Fire and Oil Resistant |

|

|

Steel cord Reinforced Conveyor Belting SANS 1366 |

|

|

Steel Cord Conveyor Belting (also available with Rip Detection Loops): Range available from ST 500 to ST 7100 (up to 2400mm wide) |

|

|

Textile Reinforced PVC Conveyor Belting SANS 971 |

|

|

Solid Woven Conveyor Belting: Available with : - Abrasion Resistant Fibre - High Abrasion and Impact |

|

References /Pictures: